Get in touch

555-555-5555

mymail@mailservice.com

FLEXOGRAPHIC BAG TO BAG PRINTING

MACHINE

Slide title

Write your caption hereButton

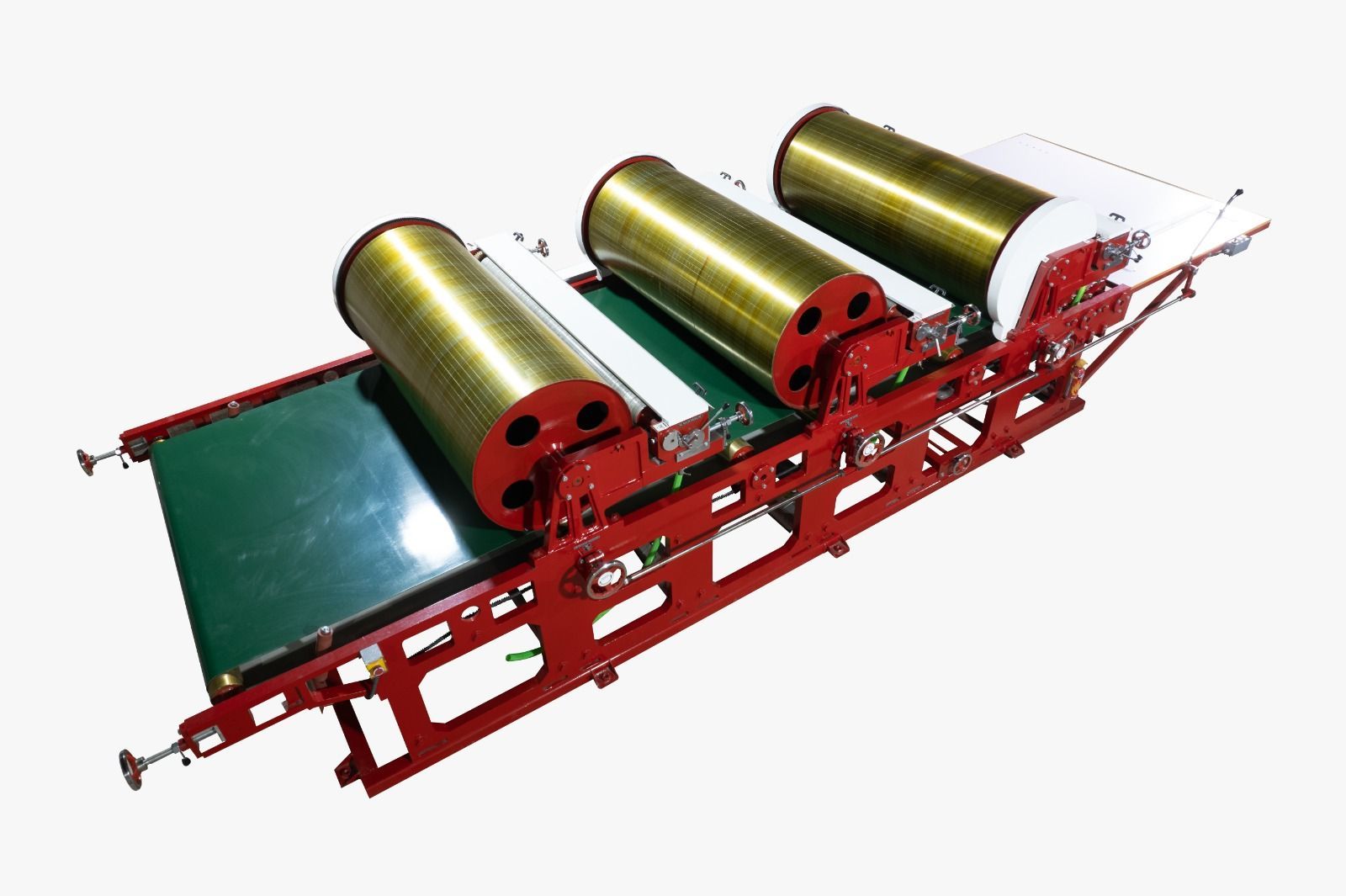

Model : Printek4

Brand : ARMSTRONG

Flexographic Bag to Bag Printing Machine

ARMSTRONG's Flexographic printing machine is a specialized printing system designed for printing large-scale bags, often made of woven polypropylene (PP), polyethylene, or similar materials. The printing on these bags serves both functional and marketing purposes—such as branding, product information, and logistics identification. The printing machines used for jumbo bags are typically large, durable, and capable of handling the heavy-duty nature of the material.

Our flexo printing is versatile, capable of printing up to 4 colors, and can handle a variety of inks (water-based, solvent-based, UV).

*Multiple substrates: perfect for printing on all kinds of packaging thanks to the flexibility and adaptability of the plate.

*High Profitability: due to the printer shape, it is possible to print long and very long runs at a lower cost.

*Faster: the inks need less drying, thus speeding up the printing process.

*Copper Coated Anilox Rolls for sharp printing & lower ink consumption.

*AC Drive System helps to save 30% electricity, control the machine speed and saves motor against voltage fluctuation.

*Bag Stopper System helps to maintain equal bottom print margin in each bag.

*Shaft Mechanism drives each station with high grade steed made gear and shaft to give error-less printing registration.

*Do Not Dirty Belt System keeps the conveyor belt print-free during missed stock with sensor based auto-pneumatic system.

*Tracking Belt System hold the bag to convey or and gives print without any error in registration

*Hard Chrome Plated Drums keep the drum surface rust free.

*Digital Counter Meter keeps track on printing production count.

*Dryer Unit will instantly dry out prints in extreme humid weather.

The one and only complete solution providers of high-quality industrial finishing machines and spare parts.

079-27543747 | +91 63587 40011/16

info@armstrongex.com

Address

OFFICE

501, ‘Sarap’, Opposite Navjivan Press

Ahmedabad, GJ - 380014, India

FACTORY

Unit 1

Plot no. A2/502-1,

Opp. Indo-German Tool Room

Phase - 4, GIDC Estate

Vatva, Ahmedabad, Gujarat 382445, India

Unit 2

44+45/A/1, Near. Ambica Bridge, Phase - I, Vatva GIDC, Ahmedabad, Gujarat 382445