Get in touch

555-555-5555

mymail@mailservice.com

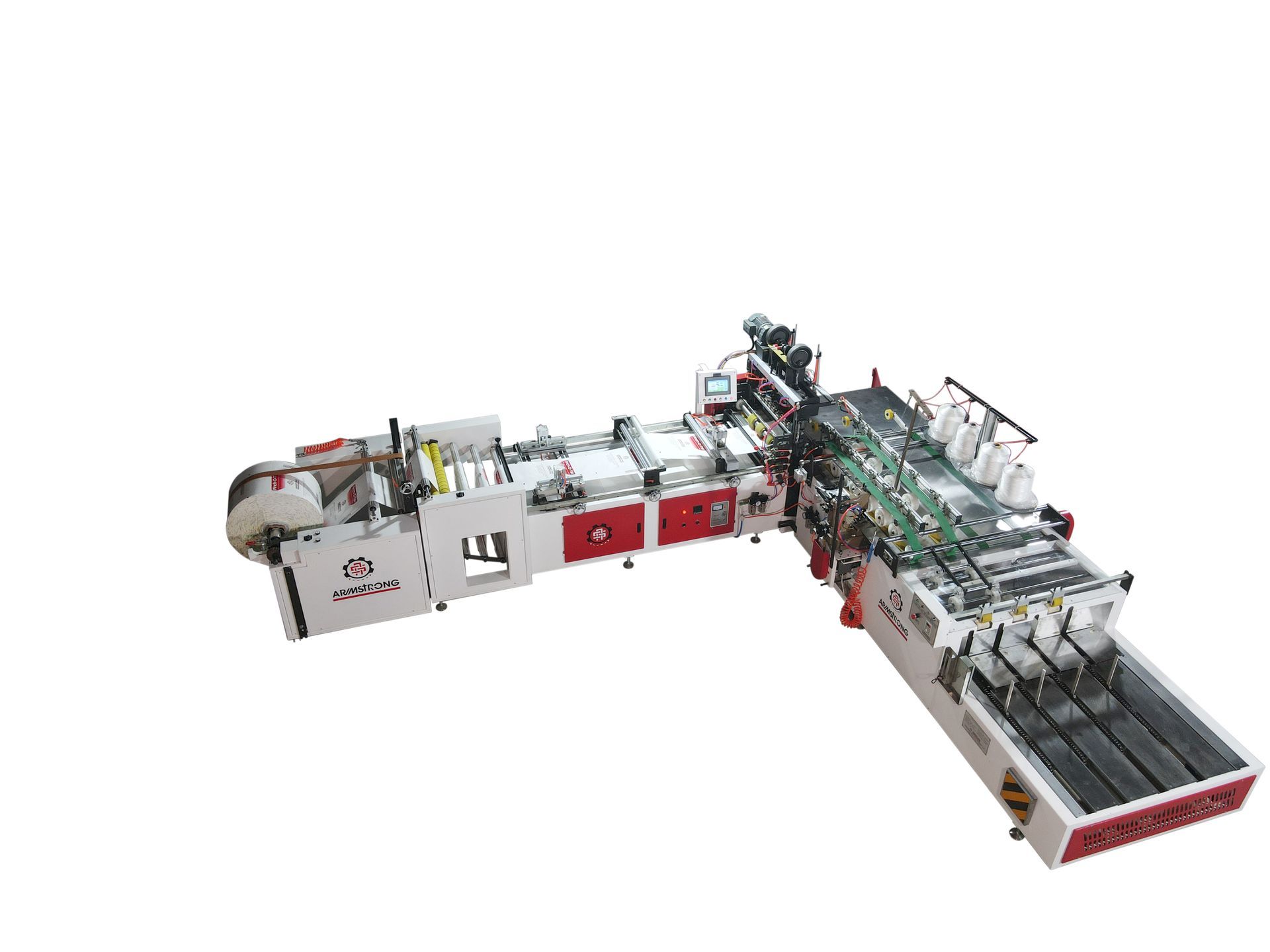

ARMSTRONG HIGH SPEED BAG CUTTING SEWING CONVERSION LINE MACHINE

HIGH SPEED BAG CUTTING SEWING CONVERSION LINE

Model: BCSTek +

Brand: ARMSTRONG

High Speed Automatic bag cutting and stitching machines have been developed for producing bottom folded and stitch woven sack made from roll of tubular woven PP/HDPE fabric. This bag machine is not only suitable for PP / HDPE but also work best in BOPP & Leno too. Our woven bag conversion system can make cement bags, BOPP bags, fertilizer bags, sugar bags and Leno bags.

High Speed BCS machine provides solution for converting laminated and un- laminated tubular fabric into bags. ARMSTRONG BCS Machine is a high-speed conversion line for cross cutting, bottom folding, sewing and finally stacking of finished HDPE/PP woven fabric bags in one continuous operation. This machine can be used for bag conversion from plain woven (non- coated or coated) and leno fabric. Special attachments for producing gusseted bags, perforated bags and bags with easy open top stitch are also available.

Production capacity: 60-70 pcs per minute

High working speed

Operator friendly design

Low energy consumption

Low maintenance cost

Equipped with servomotors.

Equipped with 90-degree bag transfer gripper.

Digital display microprocessor based.

Custom-made design are available.

Superior performance on all types of fabrics. (Laminated, un- laminated, Bopp and Leno fabric)

Features:

Max Bag Size: 34” W x 56” L

Maximum Speed: Upto 40 Bags/Min, depending upon material, width of the fabric etc.

High-Speed Fully Automatic Bag Conversion Line for PP/HDPE Woven, Leno Fabric and

BOPP

Fully Automation Servo, PLC, HMI

The one and only complete solution providers of high-quality industrial finishing machines and spare parts.

079-27543747 | +91 63587 40011/16

info@armstrongex.com

Address

OFFICE

501, ‘Sarap’, Opposite Navjivan Press

Ahmedabad, GJ - 380014, India

FACTORY

Unit 1

Plot no. A2/502-1,

Opp. Indo-German Tool Room

Phase - 4, GIDC Estate

Vatva, Ahmedabad, Gujarat 382445, India

Unit 2

44+45/A/1, Near. Ambica Bridge, Phase - I, Vatva GIDC, Ahmedabad, Gujarat 382445