Get in touch

555-555-5555

mymail@mailservice.com

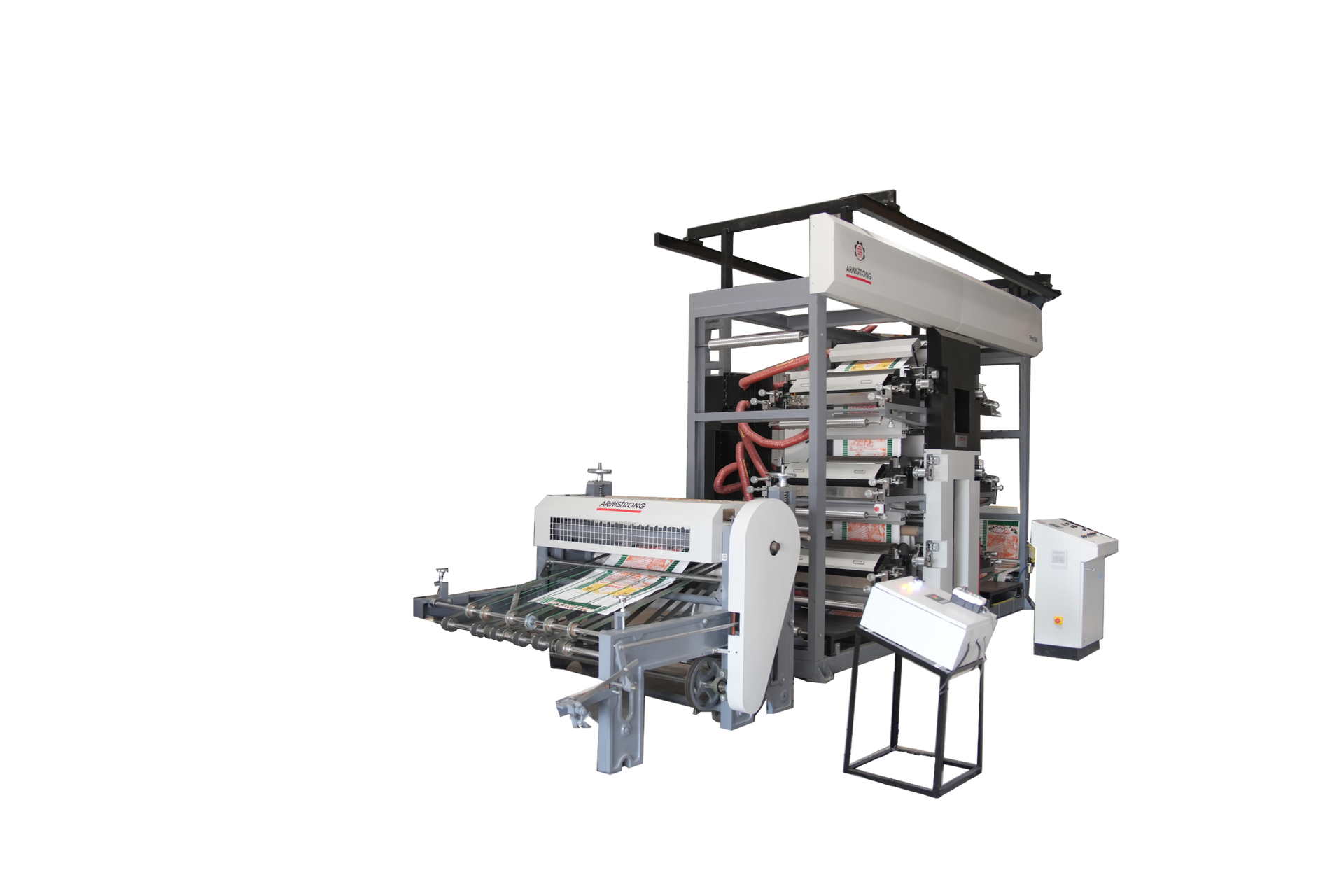

ARMSTRONG SIX COLOUR ROLL TO ROLL FLEXO PRINTING MACHINE WITH AUTO CUTTING SYSTEM

Model: R2R Flexographic Printing Machine (PrinTek 6)

Brand: ARMSTRONG

ARMSTRONG Roll to roll Flexo printing machine is used for printing texts and images on PP polypropylene roll, paper roll, plastic film roll, non-woven roll, thermal paper roll etc. Both water based ink and solvent ink are ok to use. Its advanced technology enables seamless six-color printing without changing cylinders, ensuring consistent precision and minimal downtime. This machine offers a cost-effective solution for businesses, enhancing productivity while maintaining exceptional print quality for various PP woven materials. Printing Stations Driven by Timing Belt can also be given, as per customers requirement.

A whole new design based on the previous model which had been produced over 10 year, presents our efforts for upgrade and improvement. To achieve better performance, we can equip gear boxes on each printing station. These gear boxes feature 360 degree online printing registration during machine running. An overhead drying oven is employed reel to reel printing is the most efficient way for the pp woven bag printing (especially for double side printing).The R2R PrinTek model is capable of performing 6-8 colors printing and printing and productivity up to 120 m/min, decreasing the printing cost to a minimum. More features that can be offered are : 1. Chamber Doctor Blade Ceramic Anilox Roller Ink Pumps for continuous rotation of inks Additional plate cylinder for desired print repeat lengths 2. Web video inspection system - One or both sides of the fabric. Corona System is again an optional feature to give best registration quality.

Main Features

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic operation printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break the circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

9. Automatic Edge Position Control system, can correct deviation of material, ensure material in right place.

Basic Features :

- Type: Flexographic (flexo) printing – uses flexible relief plates.

- Colours: 6-colour configuration for high-quality multicolor printing.

- Printing Material: Woven PP/HDPE fabric rolls (often laminated or unlaminated).

- Ink: Fast-drying water-based or solvent-based inks.

- Drying System: Hot air dryer or infrared heaters between colour stations.

- Registration Control: Auto registration for colour alignment.

- Printing Speed: 100 meters/min

- Printing Configuration: 6+0,5+1,4+2,3+3 (Front and Back printing supported)

- Technology: Gearless timing belt series with halftone printing capability for bags

- Heavy-duty CI frame with anti-vibration design

Cutting Assembly

*Integrated Cutter: Cuts the printed fabric into bag-sized sheets.

*Cutting Type: Hot knife or rotary blade, depending on material.

*Bag Length Setting: Adjustable as per bag size requirement.

*Stacker: Automatically stacks cut pieces for stitching or further processing.

The one and only complete solution providers of high-quality industrial finishing machines and spare parts.

079-27543747 | +91 63587 40011/16

info@armstrongex.com

Address

OFFICE

501, ‘Sarap’, Opposite Navjivan Press

Ahmedabad, GJ - 380014, India

FACTORY

Unit 1

Plot no. A2/502-1,

Opp. Indo-German Tool Room

Phase - 4, GIDC Estate

Vatva, Ahmedabad, Gujarat 382445, India

Unit 2

44+45/A/1, Near. Ambica Bridge, Phase - I, Vatva GIDC, Ahmedabad, Gujarat 382445