From Large Rolls to Precise Cuts: The Benefits of Automated Roll Conversion

One area where machines have made a big difference is converting large rolls of material

into smaller, more manageable sizes. This process, called automated roll conversion, is

essential for many industries, and it helps businesses save time, reduce waste, and meet

customer needs efficiently.

Imagine you have a giant roll of paper, plastic, or fabric that is too large to use as it is. What

if you only need a smaller piece from that roll? This is where roll conversion comes in. A

special machine takes the large roll and cuts it into smaller rolls of the exact size needed. For

example, if you have a big roll of 5,000 meters and your customer only needs 200-meter

rolls, the machine will break the big roll into several smaller ones.

These machines don’t just cut the material they also rewind it neatly onto new rolls. This is

done automatically, so there’s no need for someone to do it by hand. That’s why these

machines are called automated roll converters. They save time and make the process much

more accurate.

How Does the Machine Work?

The automated roll conversion machine is a fascinating piece of technology. Here’s a simple

way to understand how a computerised roll conversion machine works:

1. Starting with a Big Roll: A large roll of material is placed on the machine.

2. Setting the Desired Size: The operator tells the machine how long each smaller roll

should be. For example, 200 meters.

3. Automatic Rewinding and Cutting: The machine uses a unique cutting mechanism,

such as a rod-less cylinder, to precisely cut the material. After cutting, the material is

rewinded onto smaller rollers.

4. Ready-to-Use Rolls: The smaller rolls are neatly prepared and ready to be used or

shipped to customers.

The entire process happens automatically, which means less work for people and fewer

chances of mistakes.

Why Is Roll Conversion Important?

Roll conversion is a vital process in many industries. Let’s look at some reasons why a roll

conversion machine is so important:

1. Meeting Customer Needs

Every customer has different requirements. Some may need long rolls, while others prefer

shorter ones. Automated roll conversion helps businesses meet these unique needs without

any hassle.

2. Saving Time and Effort

Cutting and rewinding large rolls by hand would take much time and effort. Machines can do

this job quickly and efficiently, freeing workers to focus on other tasks.

3. Reducing Waste

By precisely cutting the material to the required size, these roll conversion machines help

reduce waste.

4. Improving Product Quality

When rolls are cut and rewound manually, uneven edges or loose winding can occur.

Automated machines ensure that each roll is perfectly cut and tightly wound, improving the

overall quality of the product.

5. Boosting Productivity

Since the process is fast and automated, businesses can produce more rolls in less time. This

means they can handle more orders and grow their business.

Industries That Benefit from Roll Conversion

Many industries rely on roll conversion to make their products. Here are a few examples:

1. Packaging Industry

Companies that produce packaging materials like plastic wrap, paper, and foil use roll

converters to prepare rolls of different sizes for their customers.

2. Textile Industry

Fabric manufacturers often need to supply smaller rolls of fabric to their clients and roll

conversion machines make this easy.

3. Printing Industry

Printers use rolls of paper, and automated roll converters help them prepare the correct

sizes for different printing jobs.

4. Labels and Stickers

Companies that produce labels and stickers use roll converters to cut large rolls into smaller

ones for easier handling and application.

Advantages of Automated Roll Conversion

Now that we know what roll conversion is and why it’s essential let’s explore some of the

specific benefits of using automated machines for this process:

1. Precision and Accuracy

Automated machines ensure every roll is cut to the required length, leaving no room for

error. This precision is essential, especially for industries where even a tiny mistake can

cause problems.

2. Cost Savings

Since the process is automated, businesses save money on labour costs. Additionally, by

reducing waste, companies can maximize the use of their materials, further cutting costs.

3. User-Friendly Operation

Modern roll converters are user-friendly. With simple controls and automatic processes,

even someone new to the machine can quickly learn how to use it.

4. Customizable Output

These devices are versatile since they can generate rolls of varied diameters. The machine

can easily handle whether a customer needs 100 or 500 meters.

Real-Life Example of Roll Conversion

Suppose a company produces plastic sheets in large rolls of 5,000 meters. A customer places

an order for 20 rolls, each 250 meters long. Instead of manually cutting the big roll, the

company uses an automated roll converter. The machine quickly cuts the big roll into 20

smaller rolls, each 250 meters long, saving time and ensuring accuracy.

Conclusion

Automated roll conversion transforms several sectors. It helps businesses save time, reduce

waste, and deliver high-quality products to their customers. These machines ensure

precision and efficiency for packaging, textiles, printing, or any other industry.

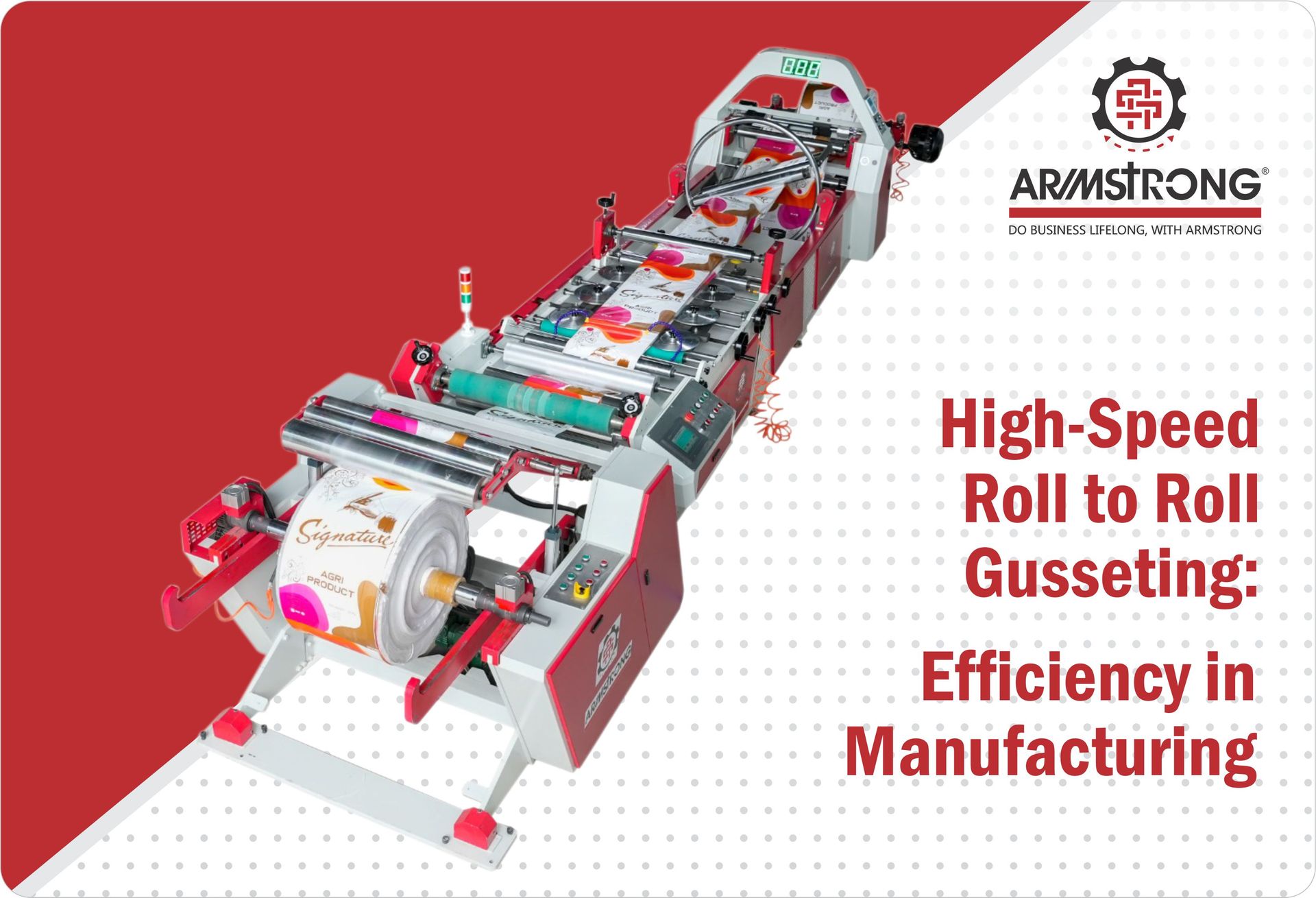

Armstong is the name to trust if you are looking for the best automated roll conversion

machines. With advanced technology and user-friendly designs, Armstong’s machines can

quickly handle your roll conversion needs. Upgrade your business with Armstong and

experience the benefits of automation today!