Get in touch

555-555-5555

mymail@mailservice.com

How to Choose the Right FIBC Bag Cleaning Machine for Your Needs

The FIBC Bag Cleaning Machine was introduced to eliminate waste in the manufacturing process, which involves rough grinding with leftover thread pieces, foreign particles, and dust inside the bag. The machine comes equipped with advanced features such as a technical eye with two cameras and LED lights for internal bag inspection and targeted cleaning.

The machine is controlled by a microprocessor for efficient operation and has automatic adjustments and waste acquisition. The cleaning process is two-way, and the design includes a static discharge installment for a smooth processing experience.

If you're searching for FIBC bulk bags to purchase, it's essential to find the ones that suit your business needs. Different types of flexible intermediate bulk containers (FIBC) have distinct advantages, particularly in industries such as agriculture, chemical manufacturing, construction, and food and beverage production.

In this article, you will learn about various types of bulk bags and identify the ones that could be most suitable for your requirements.

Considerations for Size:

When selecting FIBCs, it's crucial to choose bags that are appropriate for your product's weight and dimensions, as well as the methods you will use to handle them. For example, if you stack your FIBCs on pallets, you must select bags that fit snugly onto the pallets, without hanging over the edges or leaving too much-unused space.

If you plan to ship heavy items, it's essential to choose bags that can handle extreme weights without tearing or breaking. Properly sizing your bags will help reduce product waste, increase your profits, and prevent potential injuries resulting from improperly sized or overstuffed bags.

To determine the appropriate size for your bulk bags, you must consider two critical factors: the density of your product in pounds per cubic foot and the height and width of your existing pallets. Knowing these figures will help you purchase bags that fit correctly on your pallets.

Once you have this FIBC bulk bag specification, you can work with a professional bulk bag supplier to determine the appropriate dimensions that provide the required capacity while fitting securely and neatly on your pallets, allowing you to save valuable space.

Types of FIBC Bulk Bag

Material Types

FIBC bulk bags are categorized using a standard system that uses letters of the alphabet to indicate the bags' physical properties and protection against sparks and electrostatic shocks. The categorization system is important as it helps ensure employee safety by minimizing the risk of fires, explosions, and electric shocks.

There are four main types of FIBC bulk bags: Type A, Type B, Type C, and Type D.

Type A bulk bags are the most common and are made from woven polypropylene, calcium carbonate, and a UV additive for outdoor protection. However, they cannot store combustible products.

Type B bulk bags are similar to Type A, but they have an additional thin coating that protects against sparks.- Type C bulk bags contain carbon filaments that offer protection from flammable powders, but they lack antistatic protection. For safety reasons, these bags require grounding when being moved or filled.

- Type D bulk bags contain antistatic materials and are suitable for use with flammable powders. They protect against electrostatic shocks without requiring grounding.

- Material distinctions are critical in industries like chemical manufacturing to ensure employee safety while shipping hazardous or electrostatically-charged products.

FIBC Constructions Style

- Duffle top bulk bags:

- Closable fabric tops wrap around the overhead filling spout to prevent spills

- Flexible fabric can be wrapped in different ways to provide speed and security options

- Excellent for reducing product loss during storage and shipping.

- Spout top bulk bags:

- More rigid spouts sewn into the top of each FIBC

- Great stability during filling, best for use with certain types of fixed machinery

- Also, minimize messes and reduce product loss during storage and shipping.

- Open top bulk bags:

- Standard cube-shaped bags with an open upper area for easy manual product loading

- Ideal for irregularly shaped objects that do not fit in the bag

- Maximum airflow for perishable agricultural products, some come with ventilated strips

- Baffled bulk bags:

- Stiff panels are sewn into each side to hold a consistent, sturdy square shape

- Less volume than the open top, duffle top or spout top bags

- Excellent for stacking bags and maximizing storage space

Quality Assurance

- Bags undergo inspections for defects and discharge issues and are cleaned to minimal residue standards.

- Discharge spouts are secured, and bags are compressed into bales to reduce shipping expenses and save storage space.

- Quality assurance is crucial for bags used in food processing and agriculture to ensure safety.

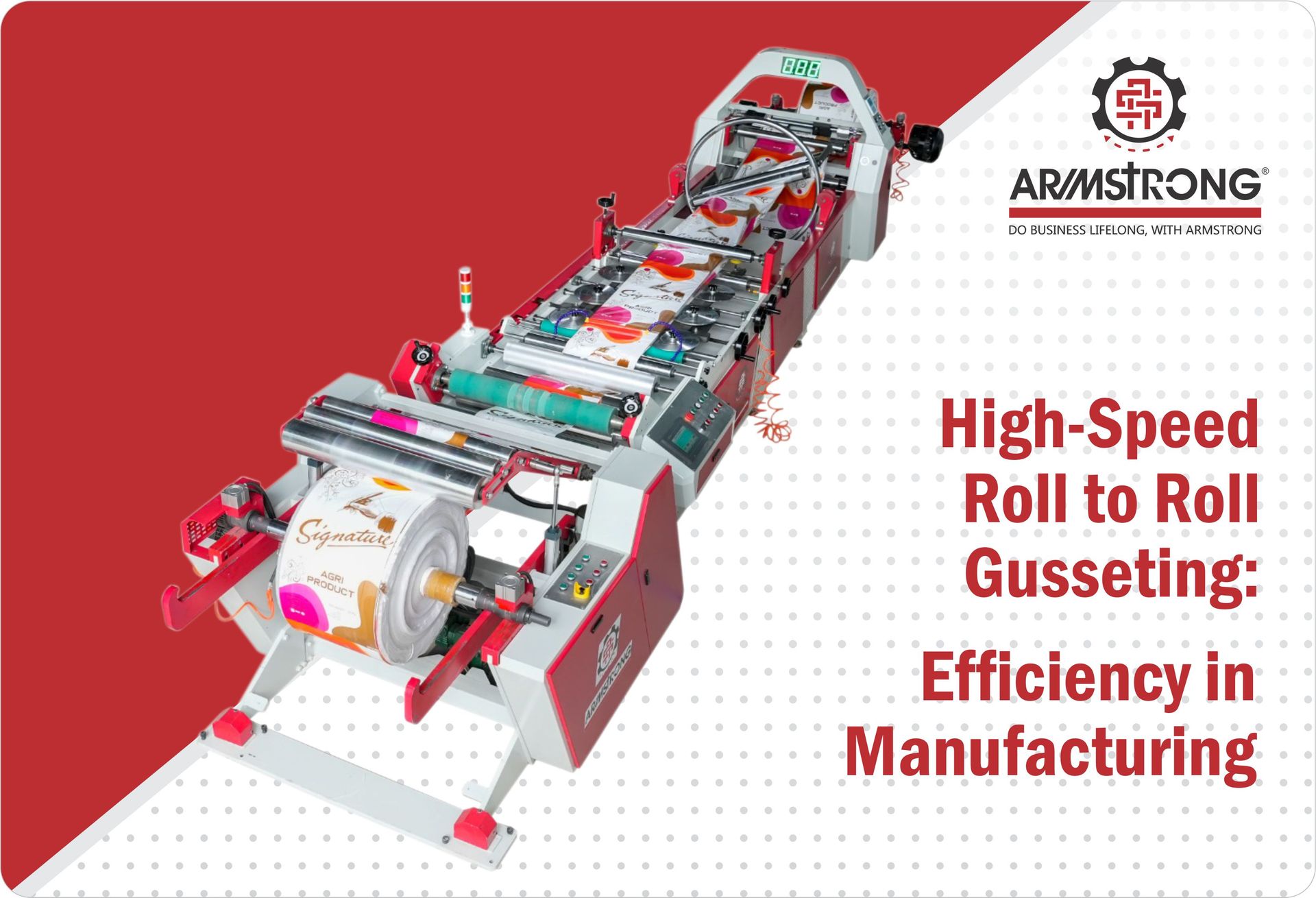

With the above-mentioned guide, you can now choose the correct FIBC Bag Cleaning machine for your business. Armstrong is a prominent manufacturer and solution provider of

FIBC bag cleaning machines, specifically designed to clean jumbo bags and FIBC bags with efficiency.

The one and only complete solution providers of high-quality industrial finishing machines and spare parts.

079-27543747 | +91 63587 40011/16

info@armstrongex.com

Address

OFFICE

501, ‘Sarap’, Opposite Navjivan Press

Ahmedabad, GJ - 380014, India

FACTORY

Unit 1

Plot no. A2/502-1,

Opp. Indo-German Tool Room

Phase - 4, GIDC Estate

Vatva, Ahmedabad, Gujarat 382445, India

Unit 2

44+45/A/1, Near. Ambica Bridge, Phase - I, Vatva GIDC, Ahmedabad, Gujarat 382445